FORGE

The Art of Forging: A Bowie Knife Project

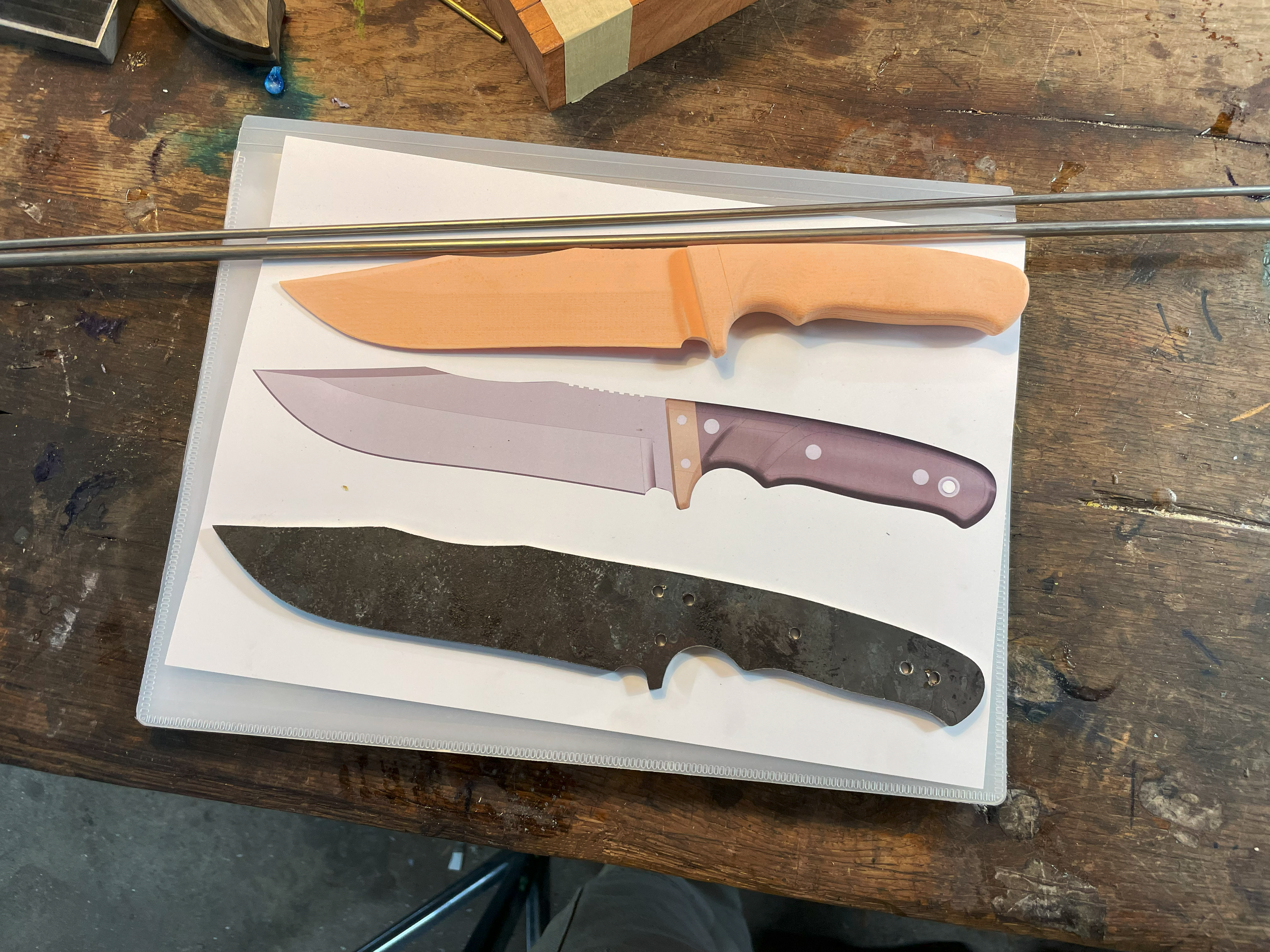

Damn, that was fun! 😊 A few months ago, I teamed up with a friend to attend a three-day blacksmithing course, where I got to design and forge my very own knife. As an industrial designer, I already had a clear vision for the design. Using Rhino CAD, I shaped the knife digitally, and then I created an ergonomic model using Ureol foam on the CNC portal mill at “Projekter” to test the grip and refine proportions before getting to the forge.

Crafting the Form

Once I was happy with the digital design, it was time to bring it to life. I traveled to the “Ruig” forge in the Netherlands, where I worked under the guidance of an expert blacksmith to shape the blade. My goal was to create a rugged Bowie-style hunting knife. The blade itself was forged from Damascus steel with a hard cutting core, a material famous for its strength and beautiful wavy patterns. Creating these patterns requires precision and a steady hand, as the process involves folding and welding multiple layers of steel.

From CAD to Steel

With the blade forged, I transferred my design onto the raw steel using adhesive films, which made it easy to outline the shape. The next step involved using an angle grinder to roughly cut the shape, followed by fine-tuning the contours with a belt sander. For the final stages, a planer with an electromagnet and horizontal grinding plate was used to achieve the perfect thickness. Precision was key to ensuring the cutting edge stayed centered during the grinding process.

Fine-tuning the Blade

Once the blade was roughly shaped, it was time for the real craftsmanship to shine through. The fine sharpening was done by hand using sharpening stones, taking care to perfect the edge with precision. After the sharpening, the blade was heated again and then quenched in oil to harden it. This step is crucial for creating the durability and sharpness needed in a high-quality knife. Once cooled, I revealed the beautiful Damascus pattern through an acid bath, which brought the intricate layers of steel to life, giving the blade its unique character. The pattern was now visible, marking the successful end of the forging process and readying it for the final finishing touches.

The Beauty of Cocobolo and Brass

The handle was crafted from Cocobolo, a stunning wood with a rough, bold texture and rich reddish-brown hues. Its unique grain, combined with black streaks and irregular patterns, made it the perfect choice for a knife handle. Cocobolo is not only visually striking but also incredibly durable, ensuring the knife would stand the test of time. The guard, made from brass, served as both a functional component and an aesthetic accent, providing a smooth transition between the handle and the Damascus blade.

Final Touches

The final step in the process was sharpening the blade. The expert blacksmith took care of this, ensuring the edge was flawless. The result was a visually stunning and functional tool. It was an amazing journey from concept to creation, and I can’t wait for the next one. If you want to try it for yourself, I highly recommend the “Ruig” forge in the Netherlands! http://www.ruigsmeden.nl